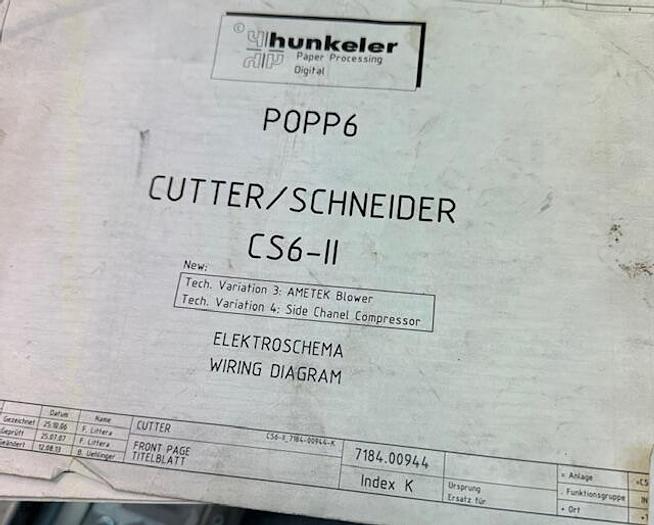

2013 Hunkeler CS6 II

2013 Hunkeler CS6 II

Description

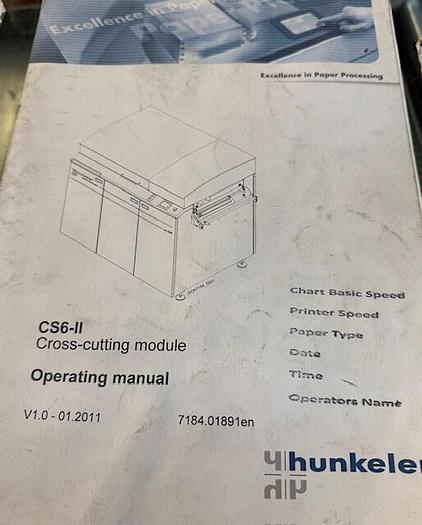

The purpose of the CS6-II is to cut a continuous paper web into sheets using a rotary single or double cut cylinders (with chip out). It can handle a variety papers, ranging from lightweight newsprint to card stock. The cutter can be used with most digital continuous printers, as well as offline with an unwinder. Its capabilities extend from 1-up to 4-up production. On-Line from Printer Off-Line from Roll.

The paper web, arriving from the pre-processing module, is fed in by the pinless infeed roller to the cutting cylinder which cuts the paper web using a rotary knife. Directly after the cutting process, the sheets are conveyed to the post processing module by a sheet outfeed mechanism. The post-processing module can be almost any type of equipment such as a stacker, buckle folder, or shingle delivery. Chip out: The CS6-II cutter is capable of cutting a chip out of the web. The chip out length is set electronically. Chip out mode can be activated, or deactivated via the panel to handle any kind of pre-printed or blank paper. Blank sheets caused by the printer's start-up procedure can be automatically diverted using the integrated dynamic diverter and are not passed on to the post-processing module. Any sheets cut during the set-up procedure are also automatically ejected by the diverter. Document control (e.g. offsetting, stack separation) is controlled by either a counter, separation marks, barcodes, or markless.

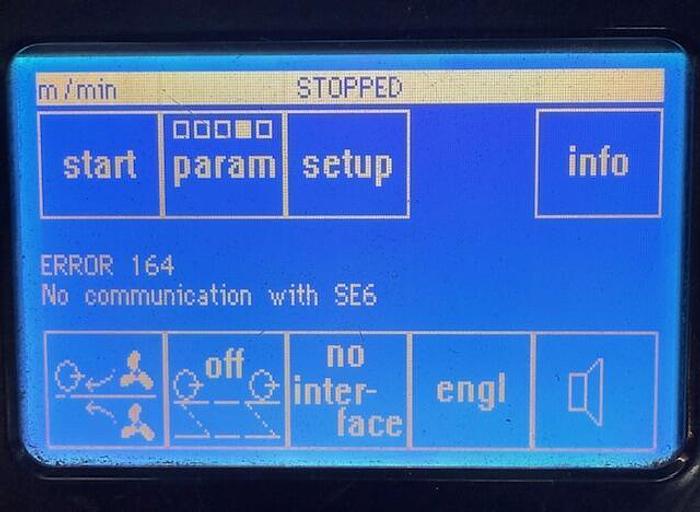

Basic equipment Basic module with two rotary high-performance shear type cutting cylinders User-friendly touch screen machine terminal for set-up and basic operating functions Casing with safety monitoring

Specifications

| Manufacturer | Hunkeler |

| Model | CS6 II |

| Year | 2013 |

| Condition | Used |

| Stock Number | 2512 |